Through different process combinations and computer simulation systems, various new sewage treatment technologies and equipment are developed for different water quality such as municipal sewage and special industrial wastewater. In the simulation system, the choice of equipment, agents, design and operation parameters and the determination of the specific process.

The platform covers an area of 240m2, including urban sewage comprehensive treatment technology experimental platform, industrial wastewater efficient treatment technology experimental platform, difficult to degrade industrial wastewater biological pretreatment technology experimental platform, urban sewage sludge process reduction and resource reuse experimental platform, wireless remote control system, etc.

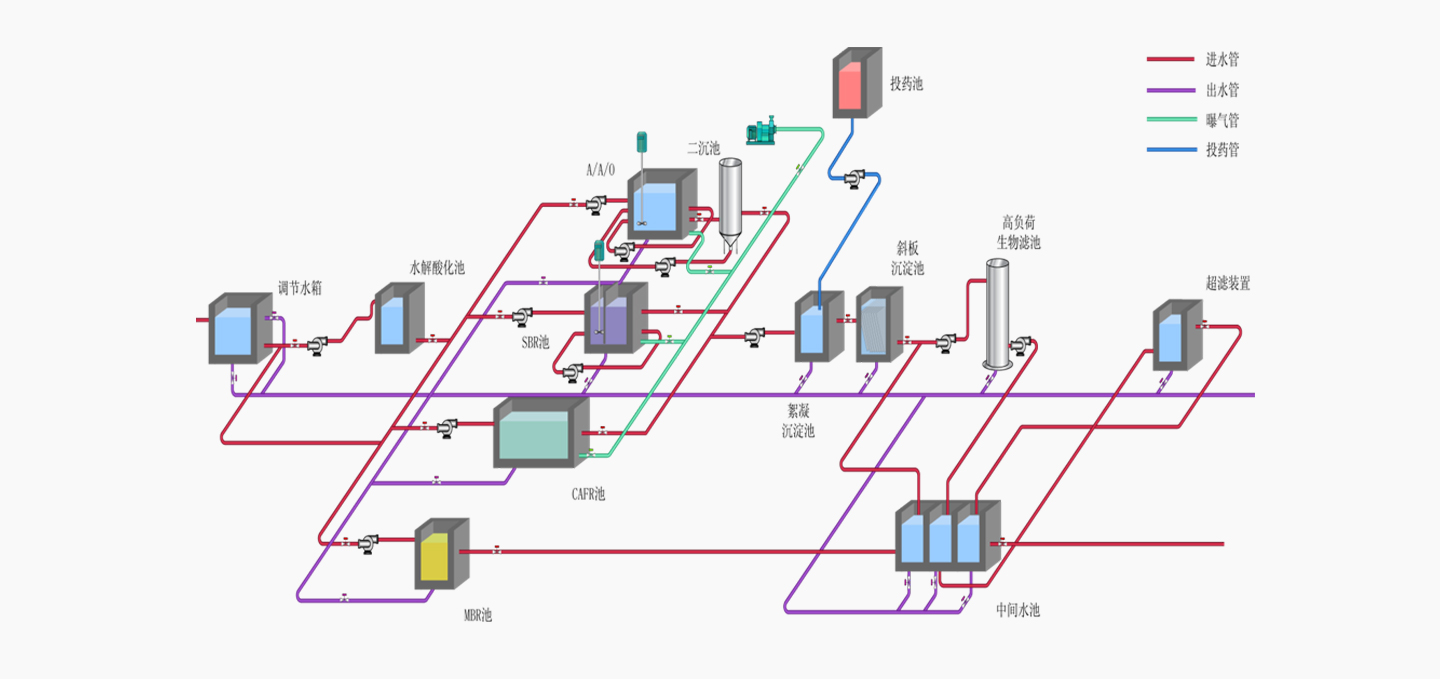

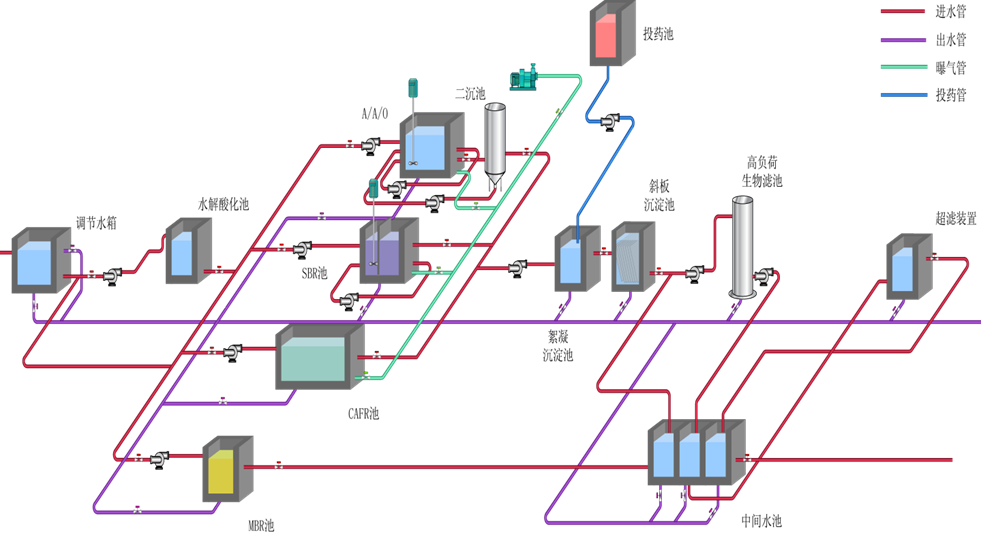

1. Experimental platform for comprehensive treatment of urban sewage

The experimental platform design processing scale is 20L/h, including secondary treatment unit using common process types (A/A/O, SBR, MBR) and new biological treatment CAFR process unit, in addition to water pump, air compressor, peristaltic pump, online instrument, wireless network control system and other equipment. It can be applied to urban sewage treatment, reclaimed water reuse, wastewater in-depth treatment, etc., to meet the discharge standard of domestic sewage grade B, or to meet the requirements of reclaimed water reuse. Each equipment unit of the platform is independent and mobile, which is convenient for access of other platforms or key process equipment units.

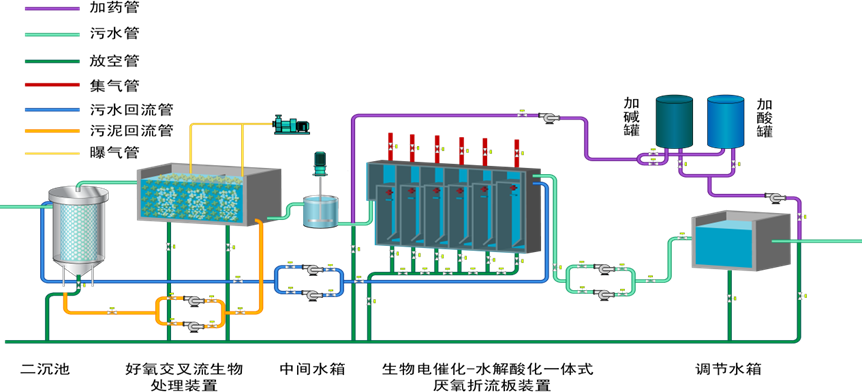

2. Experimental platform for biological pretreatment technology of refractory industrial wastewater

The experimental platform was designed with a treatment scale of 5L/h, with the bioelectrocatalyzation-hydrolytic acidification integrated anaerobic baffle device as the core, supplemented by five process units: regulating water tank, intermediate water tank, aerobic cross-flow biological treatment device, secondary sedimentation tank and acid-base regulation tank. It can be used to treat chemical, printing and dyeing, pharmaceutical waste water which is difficult to be degraded by aerobic biological method, and finally discharge to standard. Each equipment unit of the platform is independent and mobile, which is convenient for access of other platforms or key process equipment units. The biggest feature of this platform is that bioelectrocatalysis is introduced into hydrolytic acidification process to form a bioelectrochemical integrated system with independent intellectual property rights, which is also the world's first pilot-scale bioelectrochemical wastewater treatment integrated process. The research content of this platform has been supported by three national Natural Science Foundation of China projects, two of which are currently under research.

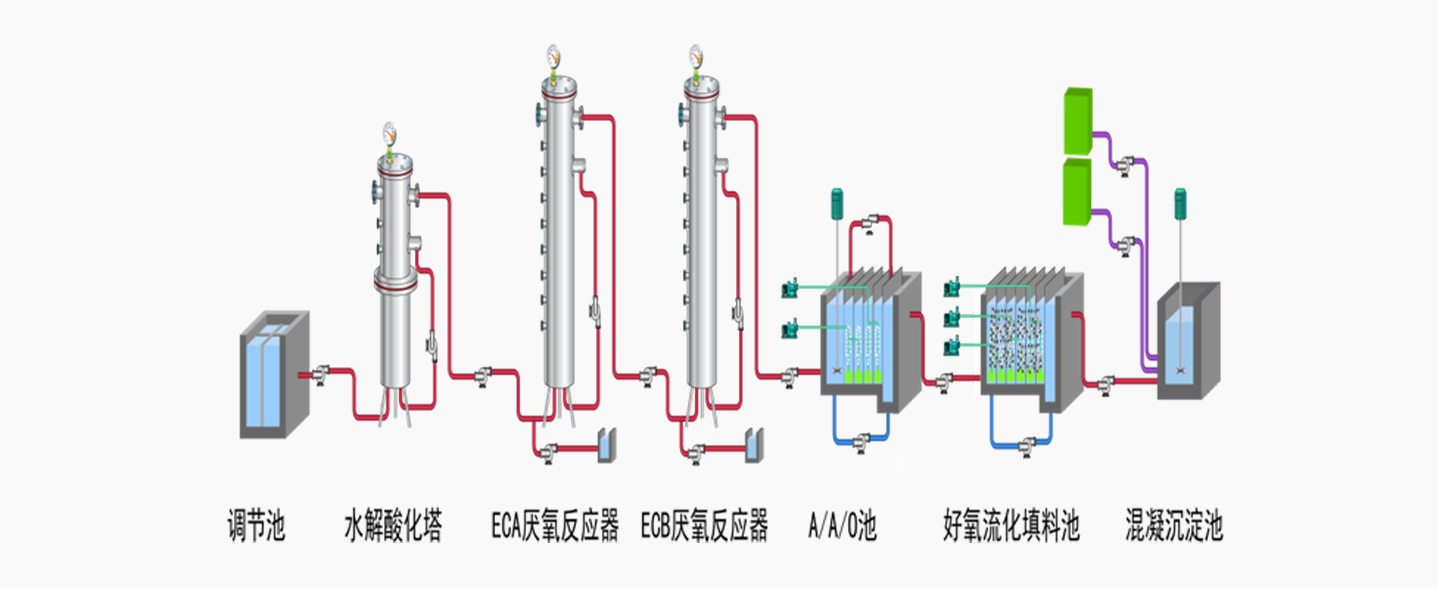

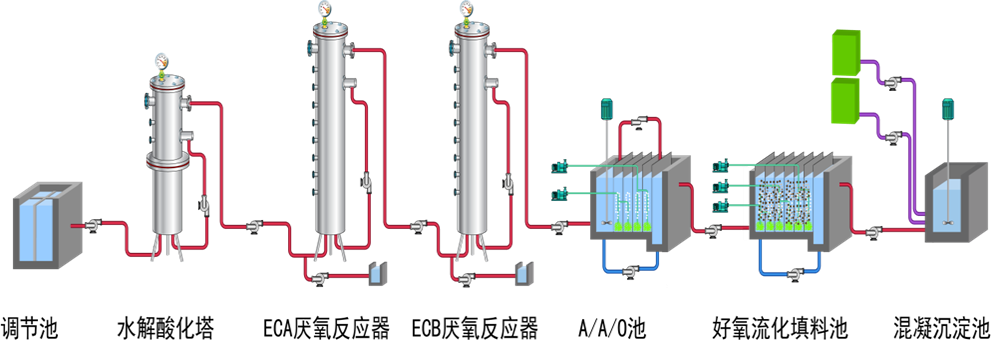

3, industrial wastewater efficient treatment technology experimental platform

The designed treatment scale of the experimental platform is 5L/h, including regulating tank, hydrolytic acidification tower, two-stage EC anaerobic reactor, A/A/O reaction tank (integrated sedimentation tank), aerobic fluidization packing tank (integrated sedimentation tank), coagulation sedimentation tank and other functional units. It can be used to treat urban wastewater, coal chemical wastewater, food wastewater, beer wastewater, monosodium glutamate wastewater, food deep processing wastewater, etc., and finally meet the standards of discharge. Each equipment unit of the platform is independent and mobile, which is convenient for access of other platforms or key process equipment units.

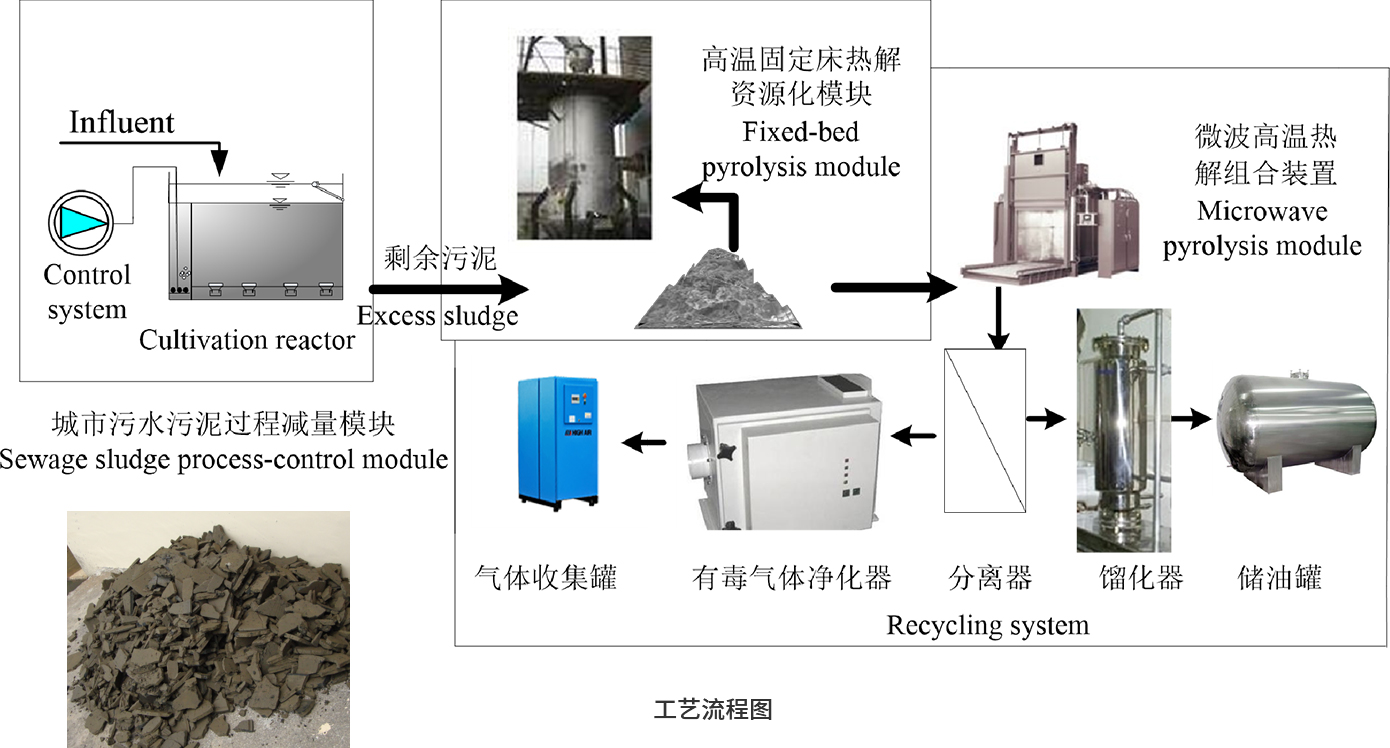

4. Experimental platform for urban sewage sludge process reduction and resource utilization

The experimental platform includes two modules, the process reduction module of municipal sewage sludge and the high temperature pyrolysis resource utilization module of sewage sludge, to analyze sewage sludge problems from the two aspects of process reduction and the resource utilization of surplus sludge.

The urban sewage sludge process reduction module is composed of sewage sludge cultivation and acclimation device, sludge property analysis system and sewage sludge cultivation and acclimation control system. It can be used for sludge reduction and resource recovery. The module can produce surplus sludge with 97% moisture content of 100~150kg/d.

The designed treatment scale of the module is 2.4kg/d, which is composed of microwave high temperature pyrolysis and high temperature fixed bed pyrolysis. The resource utilization of microwave high temperature pyrolysis includes microwave high temperature pyrolysis reactor, microwave energy control system and sludge pyrolysis product recovery system. High temperature fixed bed pyrolysis resource includes three parts: gas distribution system, heating system and reactor. It can be used for the study of efficient reduction of sludge volume, utilization of by-product resources, effective fixation of heavy metals, reduction of flue gas pollution, etc., to achieve the goal of high value conversion of sewage sludge, efficient production of biomass fuel, effective control of hazardous waste.